It is well known fact that water well hydraulics is derived from the petroleum industry, therefore borrowed the concept of synonymy between pumping and injection. Two reasons which favoured the presumption are 1. Solutions for crude oil injection were never so significant as compared to pumping in the petroleum industry, and 2. By the time water injection hydraulics necessitated, numerical modelling techniques had already overpowered the analytical solution techniques. Still the difference between well recharge and pumping may attract attention of many hydro-geologists, who appreciate classical behaviour of well hydraulics.

In technology, we are so-much of a copycat that sometimes minimum basic qualification looks relaxing. I remember the days of my initial service period, if you take a doubt to your senior officer, he will persuade that you just copy the previous sanctioned design preformats to the extent that if a total span of 9.6 m is divided into 3 spans of 3.2m each in the past design, you have no other option than to copy the number of spam even if total span is 3.3 m in the present design. Do you think it requires any specified qualification? Similarly, when the same person become head of an institution at the ultimate stages of his career and looks after the excellence in education and research as a doctorate degree holder, he could perhaps only see through the window glasses of his cabin, degrading values of his academic qualifications. Ultimately the job he peruses can be better handled by even an illiterate person, just copying and signing documents.

Most interesting in this regard is the time one spends as scientist in water sector; hardly somebody has demarcation line between investigation, design and research. Many times researchers are merely investigating and designing to show it as research and more often investigators establish better research products than a basic researcher. Where lie the utility of much hyped academic qualification?

It is well known fact that water well hydraulics is derived from the petroleum industry, therefore borrowed the concept of synonymy between pumping and injection. Two reasons which favoured the presumption are

1. Solutions for crude oil injection were never so significant as compared to pumping in the petroleum industry, and

2. By the time water injection hydraulics necessitated, numerical modelling techniques had already overpowered the analytical solution techniques.

Still the difference between well recharge and pumping may attract attention of many hydro-geologists, who appreciate classical behaviour of well hydraulics.

Characteristics discussed in well hydraulics

In well hydraulics, two characteristics which are widely discussed are; well storage and well loss. The well behaviours are quite different during the processes of pumping and recharge and hence the characteristic parameters. They could be explained as;

1. During pumping, well storage comes in to the picture only in the initial period, afterwards it is all about drawing water from the aquifer. Whereas recharge process can only be augmented with well storage in place, hence dominates the entire period. Consequently, constant well storage consideration in pumping solution is nearly realistic, however for recharge cases, it is highly unrealistic. In recharge case unsteady well storage is governing factor, as maintaining a constant well storage is difficult if not impossible.

2. Well loss computation during recharge is not straight forward, as it is during pumping. It is due to the difficulty in transforming the mirror images. More-over pumping rate can be kept as constant, however recharge rate seldom remains constant, and rather it diminishes gradually with progression in recharge process. During recharge, well loss is governed by the clogging of the well face and adjoining aquifer, friction in the well face and velocity gradient between the well and the aquifer. These considerations are rarely thought of in pumping solutions.

Figure 1: Comparison of the Recharge solutions with Cooper et al. (1967)

Figure 2: Comparison of the Recharge solution with Papadopoulos and Cooper (1967)

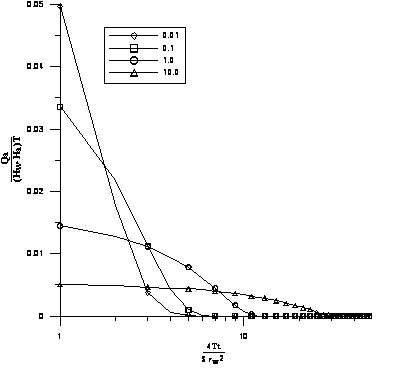

Figure 3: Non-dimensional recharge rate for different friction parameter, k

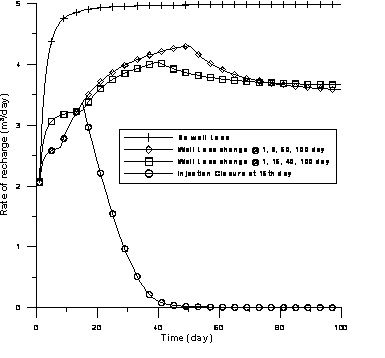

Figure 4: Recharge rate variations with variable well loss coefficient

In well hydraulics pressure solutions are described through slug test solutions and flux solutions are derived through pumping test.

Comparisons of developed solutions for recharge (Majumdar et al., 2009 and Majumdar et al., 2012) with slug test and pumping test solutions are shown in figure 1 and 2. Well loss computations in case of pressure and flux solution are shown in figure 3 and 4 respectively.

Don’t you think it takes time and courage to withstand basic research? Otherwise what is the use of academic qualification and prolonged experience? A common man can also provide water solutions.

References:

P. K. Majumdar, G. C. Mishra, M. Sekhar & K. Sridharan, Coupled Analytical Solutions for Forced Well Recharge in Confined Aquifers, ASCE J. Hydrological Engineering , 14(12), 1351-1358, 2009.

P. K. Majumdar, K. Sridharan, G. C. Mishra, M. Sekhar, Unsteady Equation for Free Recharge in a Confined Aquifer, Journal of Geology and Mining Research Vol. 4(4) pp. 75-85, May 2012

/articles/well-hydraulics-difference-hydraulics-pumping-and-recharge-dug-well