Groundwater contamination has emerged as an alarming issue in India and a recent UN report reveals that India ranks 120th among the 122 countries in terms of water quality index. As high as 70 percent of the water supply in India is contaminated, resulting in nearly 0.2 million deaths each year.

Poisoned waters: Fluoride contamination of groundwater

Fluoride contamination has emerged as one of the important concerns in India. A report by the Ministry of Drinking Water and Sanitation indicates that 14.7 million people in India face serious health hazards due to arsenic and lead contamination in groundwater.

Fluoride, a naturally occurring mineral, though essential in limited quantities for bones and teeth, exceeds the threshold concentration in a large part of the country’s groundwater affecting more than 100 million people as per estimates by Eawag researchers. It can cause damage to teeth and bones (dental and skeletal fluorosis) and other health problems such as osteoporosis, arthritis, brain damage, cancer, neurological disorders, if consumed in excess.

Geostatistical prediction models indicate that, western and southern parts of the country are more likely to be affected by fluoride-contamination of groundwater. These include the states of Andhra Pradesh, Assam, Bihar, Chhattisgarh, Delhi, Gujarat, Haryana, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Orissa, Punjab, Rajasthan, Tamil Nadu, Uttar Pradesh and West Bengal.

A unique product that removes fluoride

While, low-cost, safe, environment-friendly, easy to operate methods on fluoride removal are being developed world over, the need to develop such methods is even more urgent in India. One such effort has been made by the team led by Dr. Robin Dutta at the Department of Chemical Science, Tezpur University, Assam. This low-cost filter technology – ‘Nilogon’ that removes fluoride from groundwater is not only affordable, but is also easy to operate as a water treatment filter with high efficiency suitable for rural application.

The genesis of the initiative goes back to 1997 when the Department was setting up its laboratories. Dr. Robin Dutta at the Department was trying to do research that had societal relevance when widespread fluoride contamination of groundwater of the order of 20 ppm came to light in parts of Karbi Anglong and Nagaon districts of Assam.

A detailed survey in 1999 suggested horrifying manifestation of its ill effects i.e., fluorosis. Many schools in Karbi Anglong had over 50 percent students with dental fluorosis and a large number of people suffering from skeletal fluorosis manifesting in the form of deformed limbs, joint pain and stiff backbone. The filters available in the market were either inefficient in fluoride removal or prohibitively costly for common people. Dr. Dutta felt the urge to take up this tough challenge as fluoride was already known as a difficult-to-remove contaminant.

“While we were striving to find a low-cost and efficient fluoride removal method, the presence of deadly arsenic in groundwater in vast areas of the Brahmaputra and Barak valley of Assam was reported in 2004. I have known how it feels to have lost family and friends to deadly water contaminants,” says Dr Dutta who belongs to a village which has seen 30 cancer deaths since 1975, many of them being from his family due to consumption of arsenic-contaminated water.

With the support of students, friends, colleagues, traders, affected people, Tezpur University and funding agencies, Dr Dutta developed two do-it-yourself type simple, low-cost, safe, efficient rural technologies for removal of arsenic and fluoride by 2010 and 2011 known as - Arsiron Nilogon and Fluoride Nilogon. Nilogon means removal in Assamese.

The situation is no better in other states of the country where millions still continue to drink water containing excess fluoride. The main challenge now is in making the common people aware of these patented do-it-yourself methods, which are already being used by tens of thousands of people in Assam.

The technology behind Fluoride Nilogon

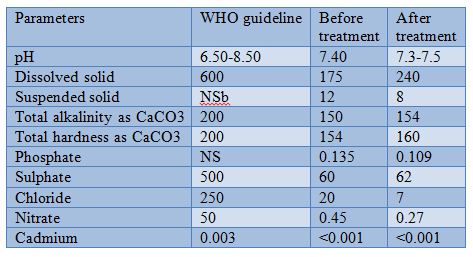

“The field trial of the patented fluoride removal method, based on precipitation-adsorption, has been carried out in some villages of Assam with groundwater sources containing 1.8-20mg/litre of fluoride at community as well as household levels,” says Asadulla Asraf Ali, a member of the team at Tezpur University. The team is trying to test for the usefulness of the technology in other states. Asadulla was testing for limestone samples in Kanker, Chhattisgarh to look for high purity calcite using XRD analysis.

Technically, Fluoride Nilogon may be called phosphoric acid-crushed limestone treatment method of fluoride removal from water. The method can remove fluoride from a high initial concentration to zero ppm. However, as a small quantity of fluoride is required for healthy teeth and bones, the final concentration of fluoride is kept at 0.65 (±0.1) ppm with this dose of phosphoric acid. The crushed limestone bed remains active for at least four years and nine months. Crushed limestone bed where the fluoride-containing water, premixed with a very small quantity of edible phosphoric acid to 0.00068 molar concentrations, is treated for a residence time of 3 hours.

Unit specification

Fluoride Nilogon units can be custom designed with any capacity of treated water.

A popular domestic Fluoride Nilogon unit of 15 litre per batch capacity requires:

- A 40 litre plastic bucket with a plastic tap for the crushed limestone bed

- About 50 kg of crushed limestone of size approximately 0.1-1.5 cm

- A filter of any type, preferably a sand-gravel filter of a 20 litre plastic bucket

A small community unit for a school consists of:

- A 500 litre or 200 litre plastic drum as crushed limestone bed

- About 625 kg or 250 kg, respectively, of 0.1-1.5 cm sized crushed limestone

- A sand-gravel filter made using a 200 litre or 30 litre plastic drum

Cost estimation

The recurring cost incurred in Fluoride Nilogon includes the cost of phosphoric acid. The cost of limestone, which has almost unlimited lifetime is included in the capital cost. The units have no maintenance costs. The market retail price of 85% phosphoric acid is Rs. 100. Thus, the recurring cost of the treatment turns out to be Rs. 0.00467 per litre of treated water. This is much lower than that of RO (approximately Rs. 0.54 per litre considering Rs. 6000 for annual maintenance and 30 litre water consumption per day) and other adsorption based fluoride filters.

The capital cost includes only the cost of two plastic containers of desired size, two taps, crushed limestone, sand and gravel. The capital cost turns out to be Rs. 600 and Rs. 4500 for household and small community Fluoride Nilogon units respectively.

“Limestone, a low-cost sedimentary rock, is readily available in most of the fluoride-affected areas of India making Fluoride Nilogon a good rural technology for fluoride removal,” sums Ali.

Tale of Tapatjuri - a film by Nilutpal Das

/articles/nilogon-fluoride-removal-groundwater