Recognizing the importance of technology in providing safe drinking water and hygienic living conditions, the Ministry of Drinking Water and Sanitation has come out with a booklet on innovative and cost effective solutions to provide potable water and sanitation in rural areas.

'Compendium of innovative technologies in rural drinking water and sanitation' lists simple technologies that can be put in place in a decentralized manner. A total of 22 water purification and treatment systems as well as 7 sewage and wastewater treatment solutions have been listed along with details about the functioning, O&M as well contact details of the service providers.

Some of featured drinking water systems include Capacititive Deionization Technology to purify water, Jal Doot ultra filtration membranes, Jal-Tara slow sand water filters to remove bacterial contamination, powdered water purification systems from P&G among others.

Contact details and working principles of different types of chemical, nano-tech as well as RO and UV based water treatment systems also find mention. Devices to track the volume of water usage, wastage and automatic water vending devices are listed as well.

Sanitation solutions

The following are some of the sewage and effluent management technologies briefly described in the booklet.

1) Soil Bio Technology for sewage and effluent treatment

A creation of IIT, Mumbai, Soil Bio Technology capitalizes on the ability of micro-organisms to consume organic and inorganic waste present in water and convert it into useful by-products. It works on simple principles of sedimentation, infiltration and bio-degradation. It ensures substantial removal of ammonia, nitrogen as well as suspended solids and bacteria; provided the wastewater is not saline, toxic to the micro-organisms and the quantity is less than five Million Litres per Day (MLD).

This requires no external mechanical or electrical energy. It uses bio-chemical processes to remove impurities in water and contributes to enriching the soil all at once. The overall operating time is around 6-7 hours and does not produce any sludge or offensive odour. Operation and maintenance is inexpensive and requires no special skill.

2) Phytorid technology for wastewater treatment

This has been developed by CSIR’s National Environmental Engineering Research Institute (NEERI) to enable reuse of wastewater post-treatment. This system employs constructed wetlands to physically, biologically and chemically treat wastewater. The systems works on gravity and requires no external power source.

Aquatic vegetation planted in specially created beds treat the wastewater by absorbing the nutrients and reduces the BOD, COD and nutrient load of the waste water. The resultant polished water which exits the system can be used for gardening. The system requires land areas of approximately 30 sq. m. to treat 25 m3 of wastewater per day.

3) Bio Digester System for human waste disposal

As sub-zero temperatures does not allow natural decomposition of human faeces, the Defence Research and Development Organisation (DRDO) felt the need to develop a system that disposes off soldiers’ waste in high altitude cold deserts like Ladakh.

Microbial inoculant culture is introduced into the septic tank like structure to digest the waste. Once through this primary microbial treatment, the partially treated liquid is put through a reed bed for further cleansing. After secondary treatment, the water can either be stored in sumps or released for agriculture or gardening.

The system works well in wide temperature ranges. The bio-digester tank along with the reed bed system can very well be used to treat grey water from kitchens and bathrooms.

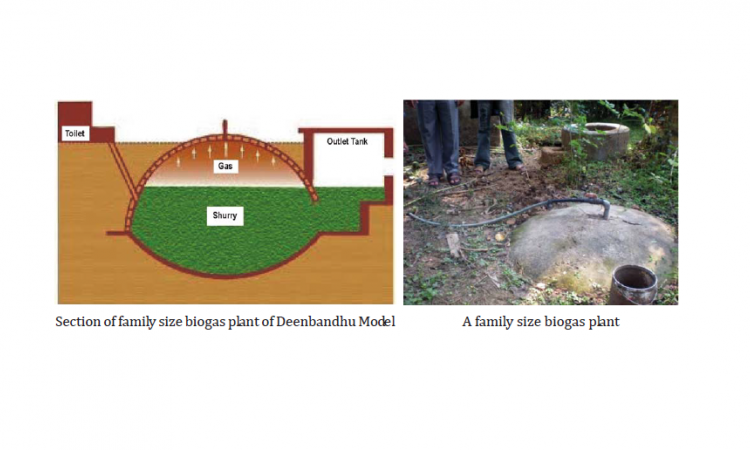

4) Bio-gas technology

Easy access to fuel can make life in villages a bit more convenient for the women who labour up hills and across plains collecting firewood for cooking and lighting. Abundance of animal and human waste opens up opportunities to produce precious fuel in the form of bio-gas provided the system is easy to use and maintain. When these bio-gas plants are linked to toilets, twin benefits of energy security as well as sanitation can be achieved.

Bio-gas is naturally produced when bacteria act upon faecal matter in the absence of oxygen. Bio-gas is mostly methane and carbon-di-oxide with trace amounts of other gases. Beside the gas, the slurry which is left behind is nutrient rich and can be used directly for agriculture.

While the floating drum type bio-gas plant, popularly known as the ‘KVIC model’ is in use, the underground RCC dome digester or the ‘Deenbandhu model’ is more popular in rural India. Animal, plant and human waste can be loaded into this system. Placing the structure in un-shaded sunlight areas help increase the ambient temperature inside the chamber, thereby increasing the bio-gas production. The bio-gas thus generated is odour free, economic and environment friendly.

5) Sequential Batch Reactor (SBR) Technology for sewage treatment

This system refines waste water that has been pre-treated, providing the highest possible efficiency in a single step biological process. Here, the treatment is divided into separate batches or cycles. Each cycle comprises of a series of steps that include aeration, settlement and decanting in that order.

Suspended particulate matter that settles down in the tank is removed while the liquid which floats above is removed from the system using a decanter. Each cycle is close to 5-6 hours duration and is repeated to treat and further polish the wastewater.

6) Membrane Bio reactor (MBR) Reactor for wastewater

This system is capable of achieving maximum efficiency in removing bacterial contamination from wastewater without the application of chemicals to aid the process.

The process involves the use of polymeric hollow fibre membranes that remain submerged in the biological treatment tank. This results in the production of high quality permeate from the sewage or wastewater that is fed into the system.

The system can be installed in a limited space as it does not require a separate clarifier tank and is much easier to operate than the conventional activated sludge process.

7) Moving Bed Bio-film Reactor (MBBR) Technology for wastewater

Thousands of polyethylene biofilm carriers move around in an aerated wastewater treatment basin providing the perfect spot for bacterial cell growth. The resultant high bacterial population density degrades the waste matter quickly.

The mobile biofilm carriers are sensitive to variations in load and adjust accordingly. The MBBR ensures the presence of an optimum level of the biofilm in the system, thereby reducing the need for constant monitoring and maintenance.

You can download the Compendium as a PDF document from the link below

/articles/compendium-innovative-technologies-rural-drinking-water-and-sanitation